A few days before leaving for Festival of the Maidens this year, I made my first attempt at engraving a coin die. The first challenge I met came in transferring the image to the steel. Professional engravers will typically either chemically transfer a printed image to the surface, or use a wax pase to mark an outline traced on top of it.

The transfer wax is more traditional and certainly closer to period, but unable to wait a month for it to arrive and unwilling to pay almost $20/oz for what may be a one-off project, I went about trying to make my own.

On searching several discussions in various engraving groups, the most basic home technique for engraving transfers if you don’t have the specialty transfer wax on hand is to use straight unscented lip balm or bowstring wax. However, I had no bowstring wax on hand, and I found lip balm to be both easily prone to smearing and too hard to see when applied in the thin coat necessary for a clean transfer.

Deciding to take a crack at making my own transfer wax, I searched for recipes. Being a very niche question in an already niche topic, most of the information I found came from discussions on engraver’s forums. There is no catch-all home recipe, but the general consensus among engravers is a 50/50 mix of beeswax and some sort of soft fat or oil paste provides the best consistency, with a bit of lamp black, charcoal, or graphite mixed in for better outline visibility.

I was unable to find a definite source for a period recipe, but it would have likely been tallow mixed with the beeswax, given its abundance and known uses for things like soap, candles, and skincare. Instead of tallow, I elected to use lip balm, for three reasons:

- I had a lot of excess lip balm and no excess tallow on hand

- Lip balm has approximately the same consistency as rendered tallow at room temperature

- Tallow can eventually go rancid if stored for long periods of time

To make the wax, I measured out equal parts of beeswax and lip balm (approximately 30g each), and melted them on low in an old stovepot.

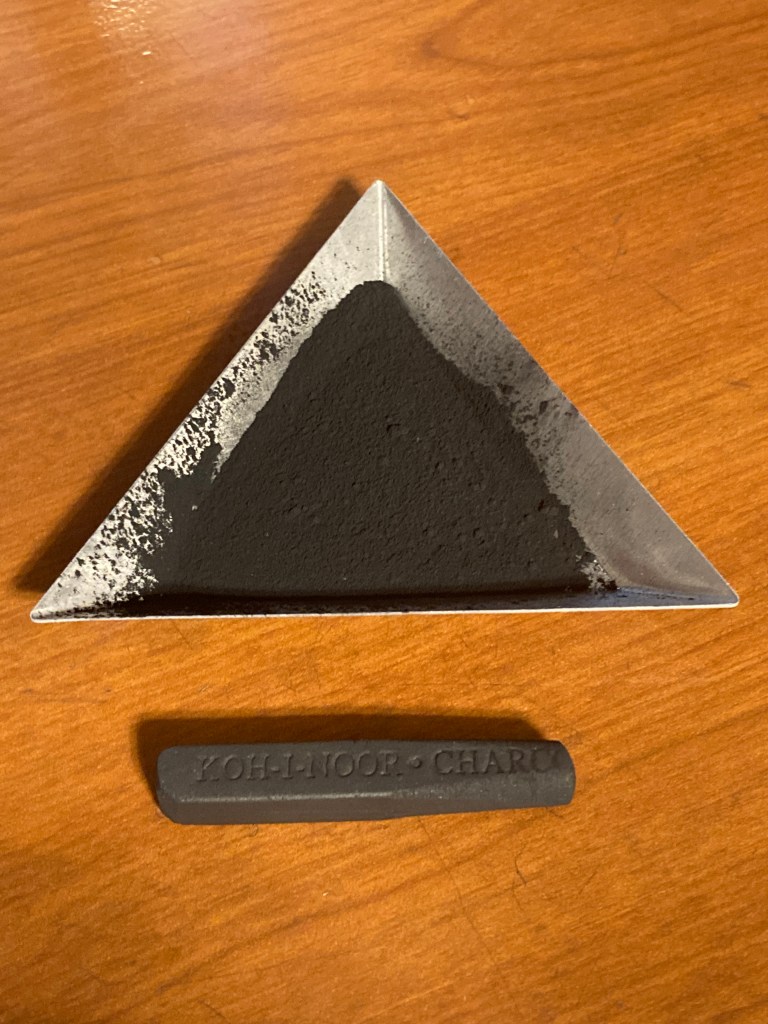

For color, I took a high grit file to a stick of artist’s charcoal to create an extremely fine black powder, and added it to the pot. For this quantity I used about 3 tsp, but you just need to add until the mixture is a deep black (it will lighten somewhat when it cools).

I initially poured the mixture straight into a small metal tin to cool, but because the powdered charcoal is relatively heavy compared to the wax it ended up all sinking to the bottom as it cooled.

To avoid this, pour the wax mixture out onto a sheet of parchment paper, and once it has cooled down enough to peel off the paper but not completely set, thoroughly knead the mixture with your hands until it reaches an even color and consistency. If you let it cool all the way before kneading it, it will be much harder to break up and have a tendency to form small beads of unmixed wax while kneading, giving it a rather poor consistency.

Once completely mixed, scrape the wax into a container of your choosing, let it completely cool down, and you’re done! A small tin like this should be enough transfer wax to last you years.

This recipe is not perfect, but it worked well enough to mark outlines for a coin die. I plan to do a comparison test in the future of different professional products and home ethods to see which works best.

Simplified Instructions

- Melt together equal parts (by weight) beeswax and some sort of heavy fat or oil such as tallow, lip balm, or petroleum jelly (the firmer the better) over low heat. if the mixture begins to smoke, .

- If using a natural fat such as tallow, make sure it is clean and fully rendered. Any impurities will cause it to go rancid relatively quickly.

- If the mixture begins to smoke, reduce the heat or switch to intermittent heat instead of constant. You do not want the wax to start evaporating.

- Mix in a finely powdered black pigment, such as lamp black, charcoal, or graphite. Add around 1/2 tsp. at a time until the mixture is a deep black color.

- In my experiment I used a ratio of approximately 1 tsp. for every 10 g of beeswax in the mix.

- Remove from heat and pour onto a sheet of parchment paper.

- As the mixture cools, thoroughly knead it either by hand (wearing rubber gloves) or using a mixing tool such as a small silicone spatula or a palette knife.

- Once the wax has reached a uniform color and consistency, scrape it into a container of your choice.

- Once cooled completely, the wax is ready for use.

Research & Resources

Engraver’s Cafe – Transfer Wax Alternative

Inter-Kingdom Moneyer’s Guild – Transferring a Design to a Die using Engraver’s Wax

Leave a comment